You can find more detailed information and technical data in our catalogue.

Click to PDF Catalog

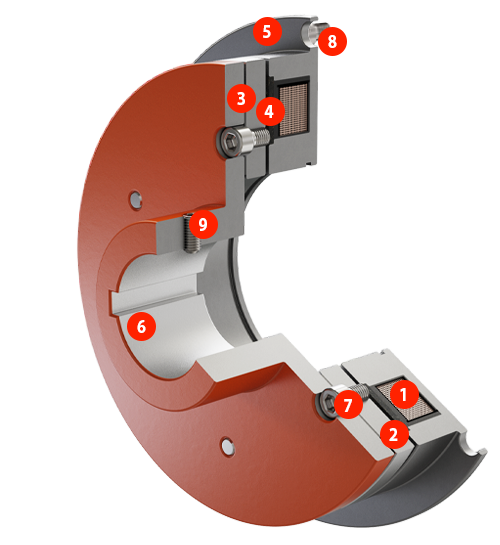

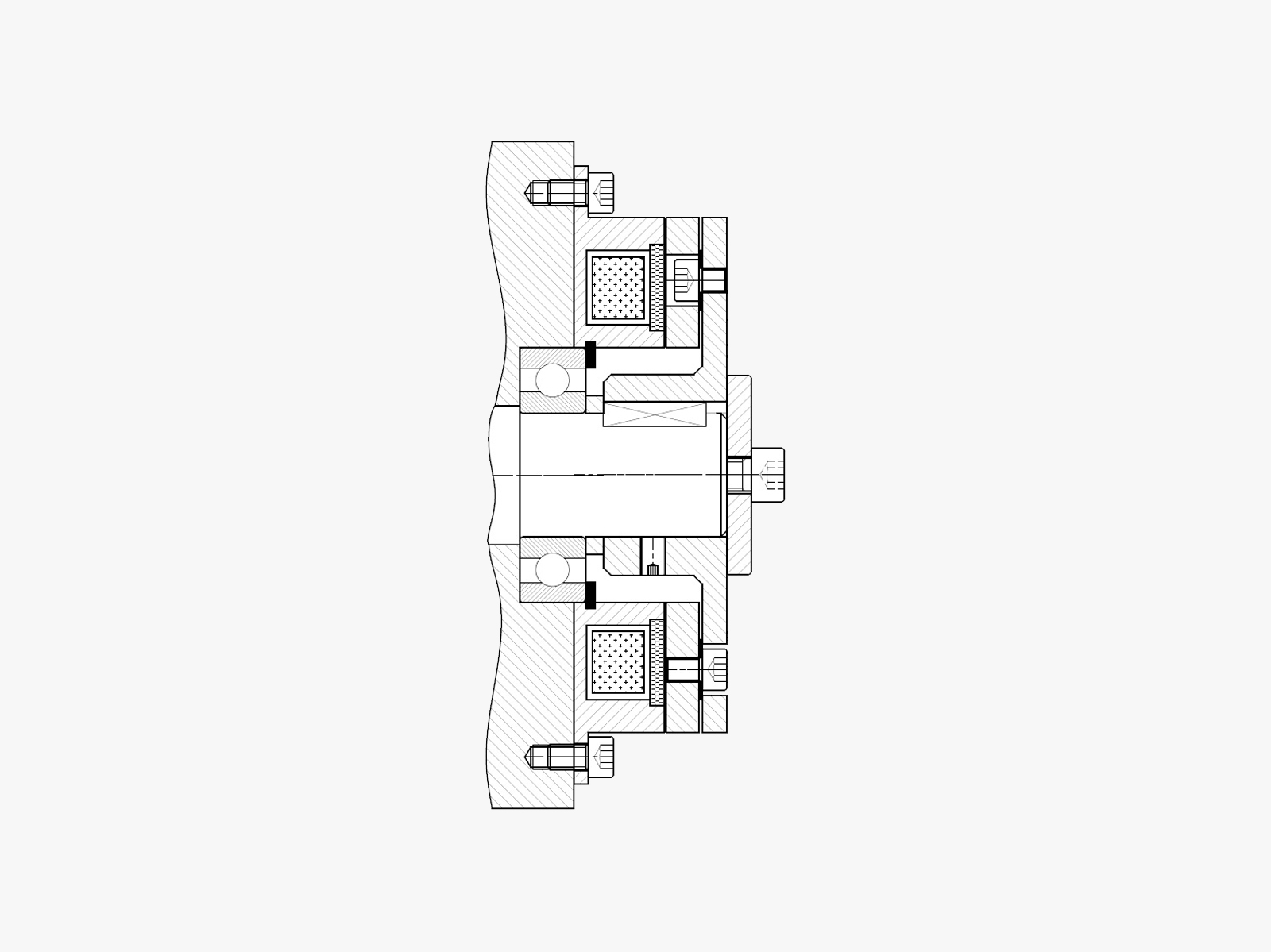

Product Features:

1Brake Coil

2Pressure Flange

3Lamella Spring

4Brake Pad

5Brake Body

6Armature

7Pressure Flange Assembly Screw

8Brake Connection Screw

9Shaft Fixing Set Screw

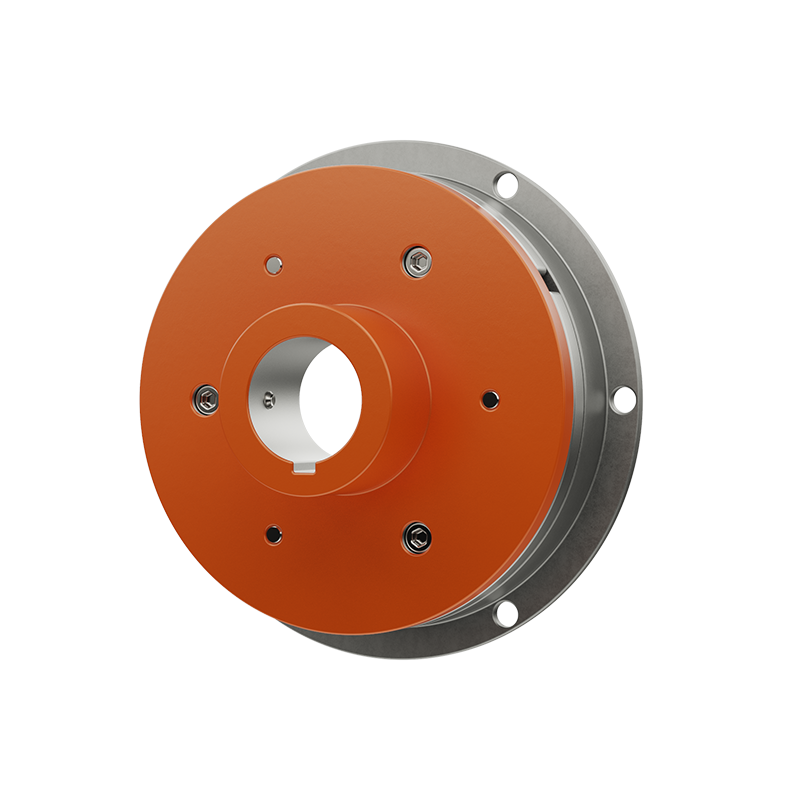

DAF Design 1.1

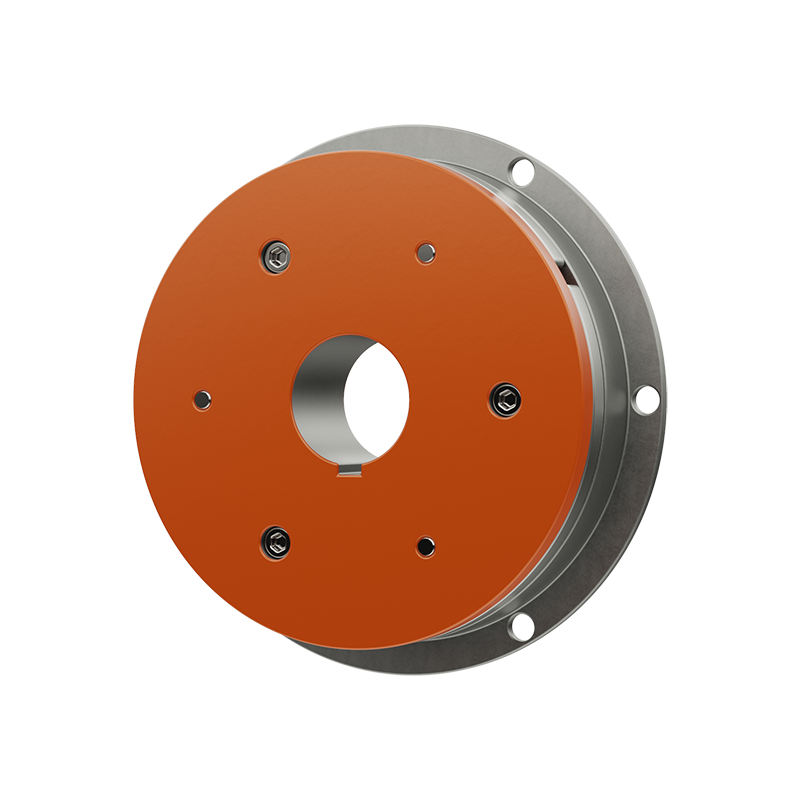

DAF Design 1.2

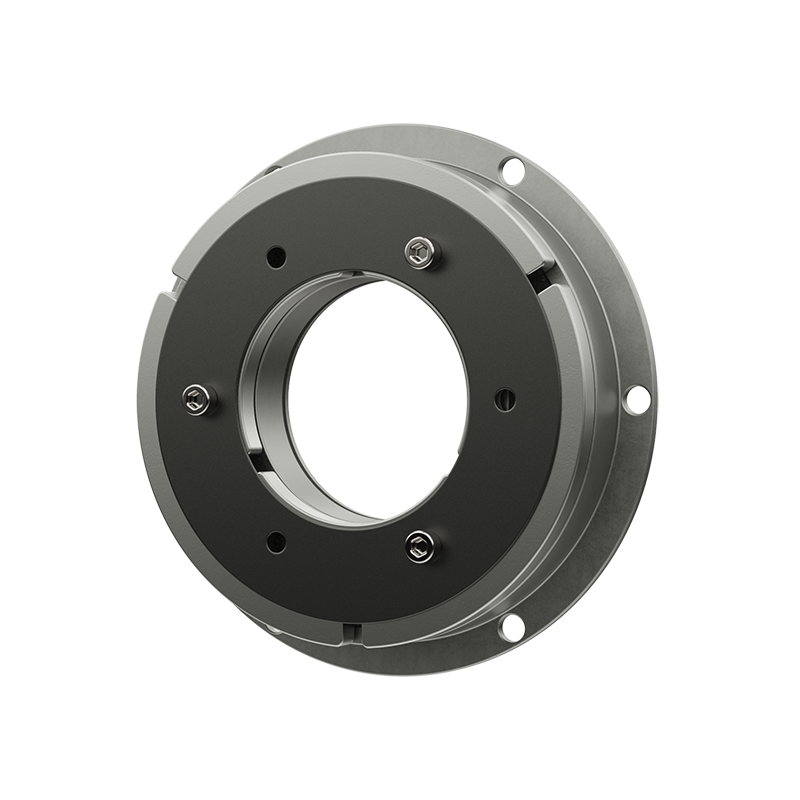

DAF Design 1.3

DAF 1.2 Assembly Type

You can find more detailed information and technical data in our catalogue.

For more detailed information about the products in Dereli, please click on the titles.