You can find more detailed information and technical data in our catalogue.

Operating Principles

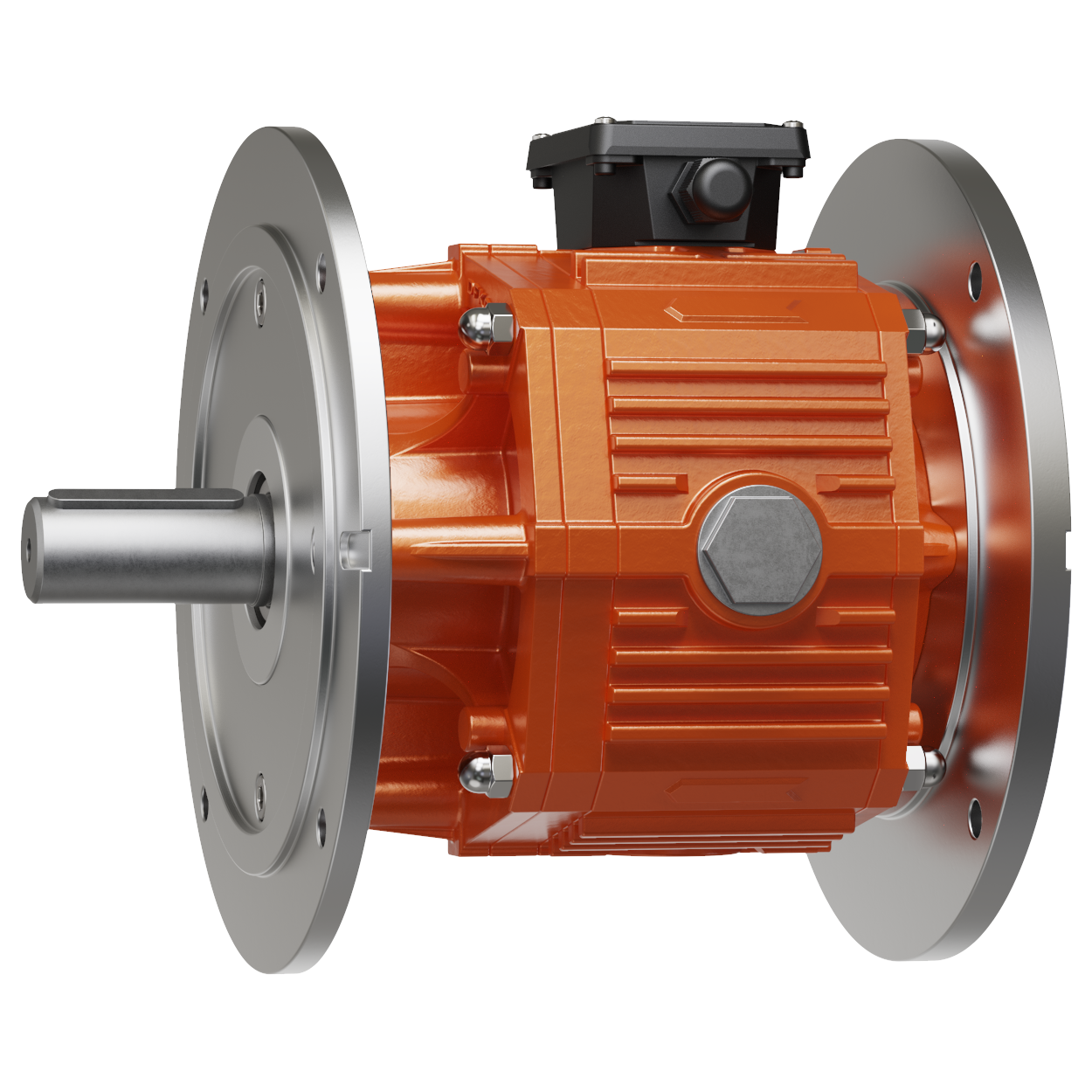

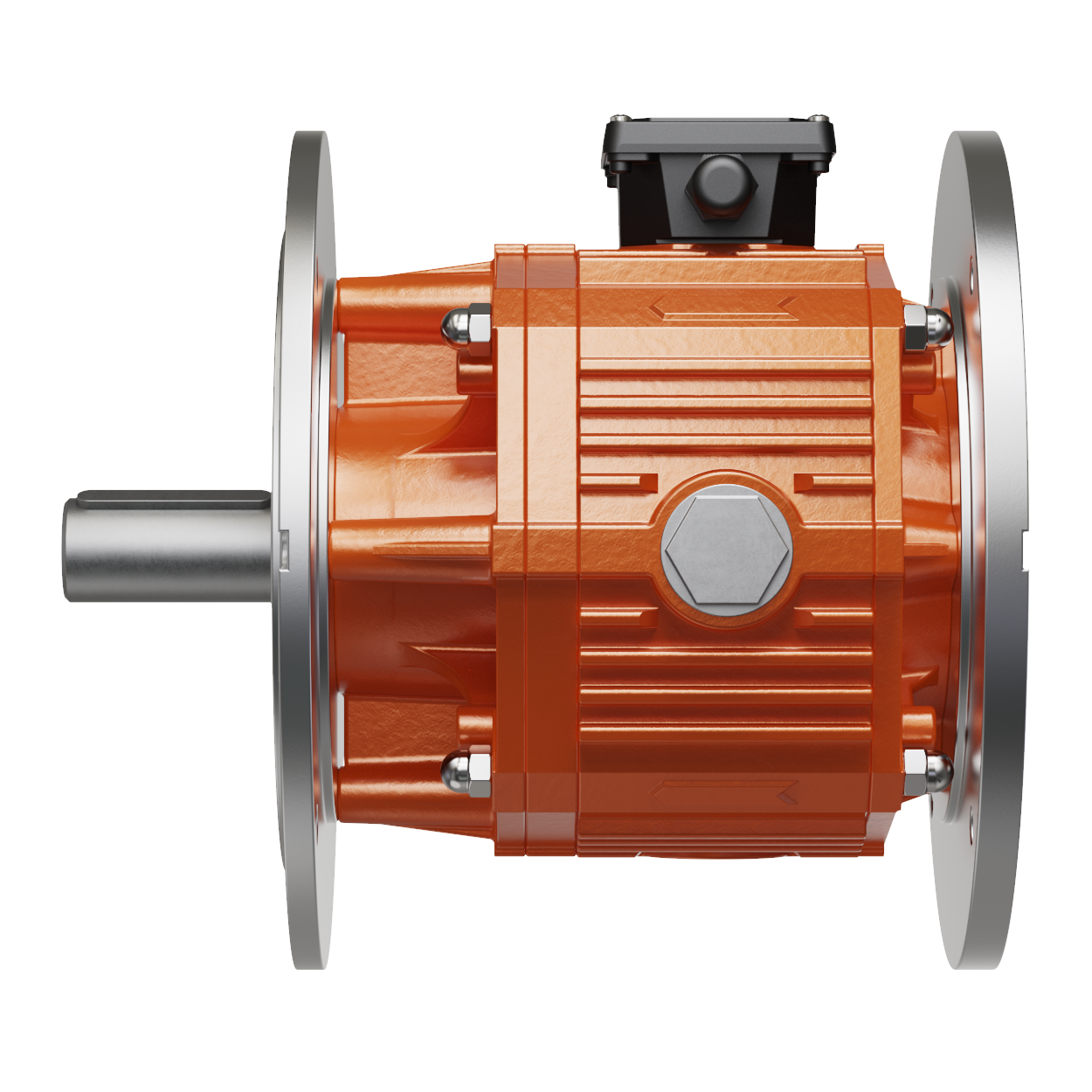

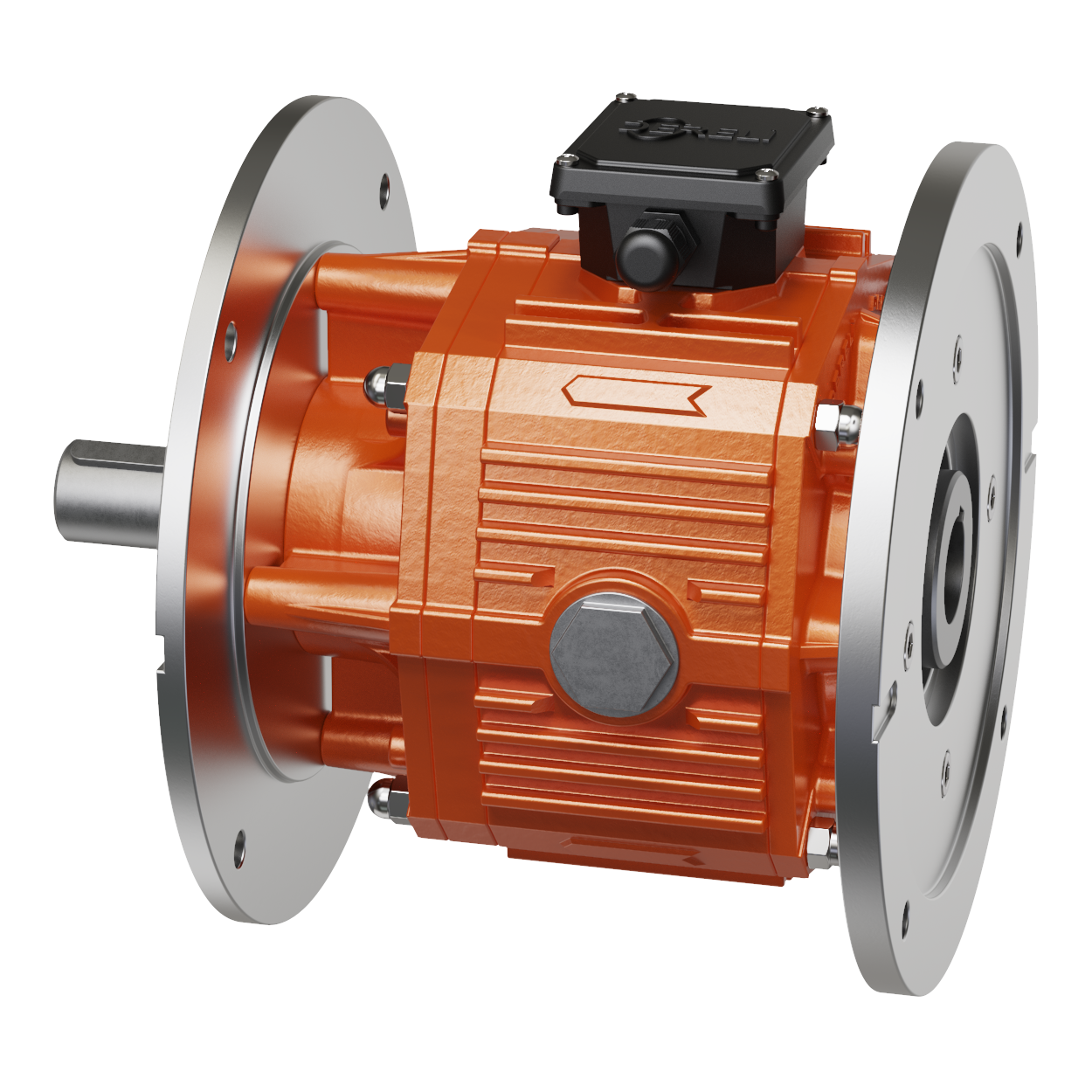

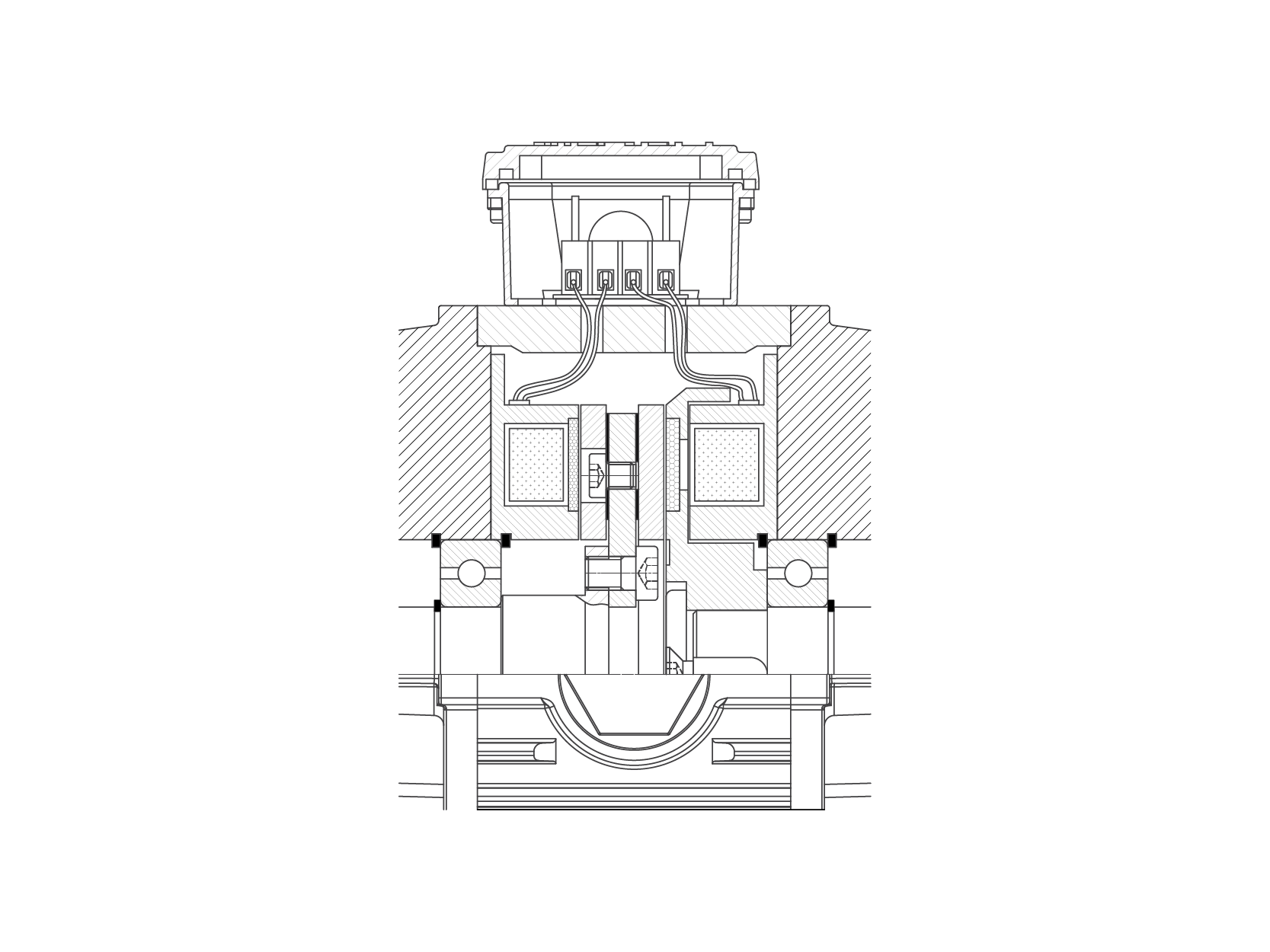

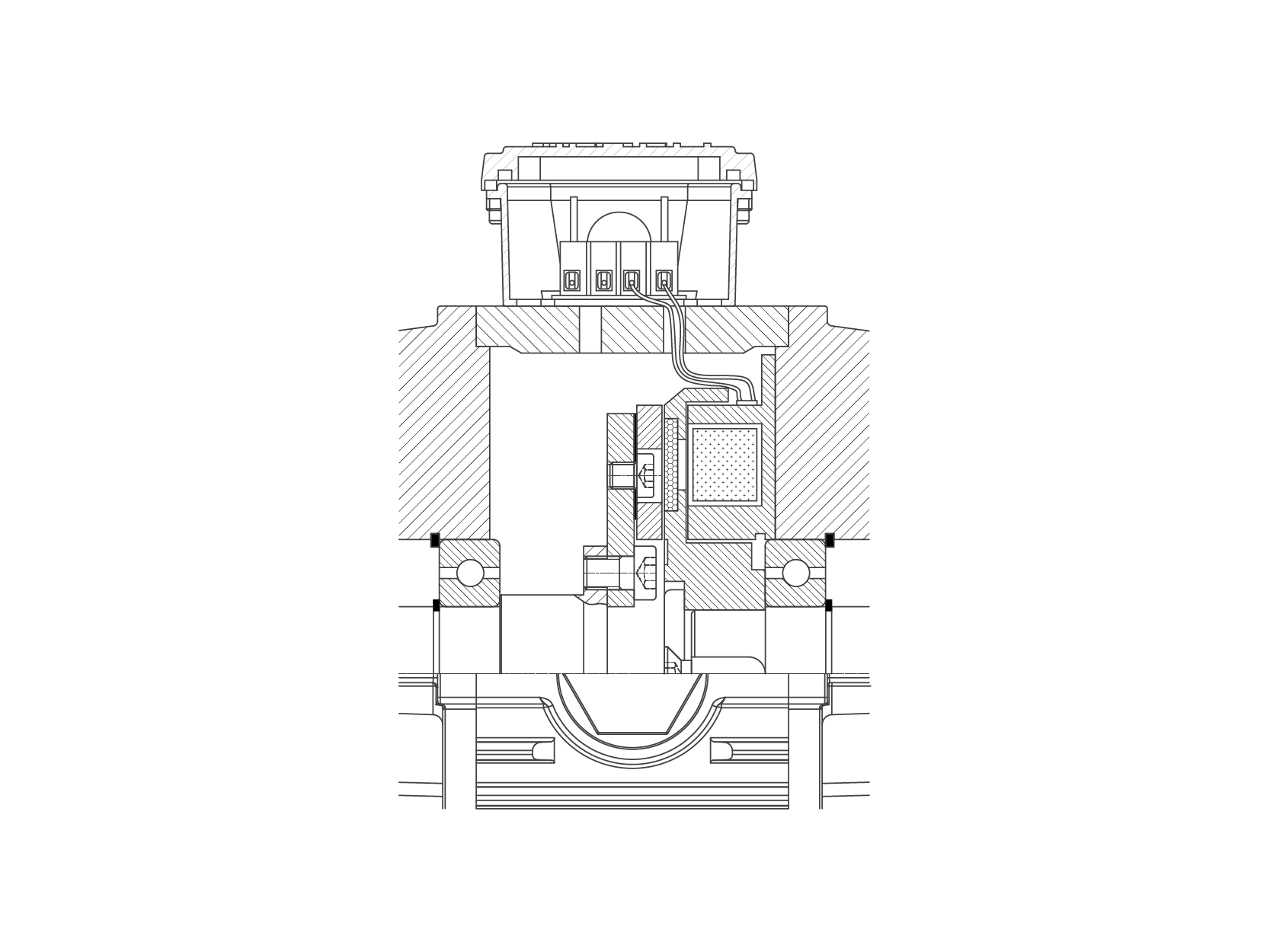

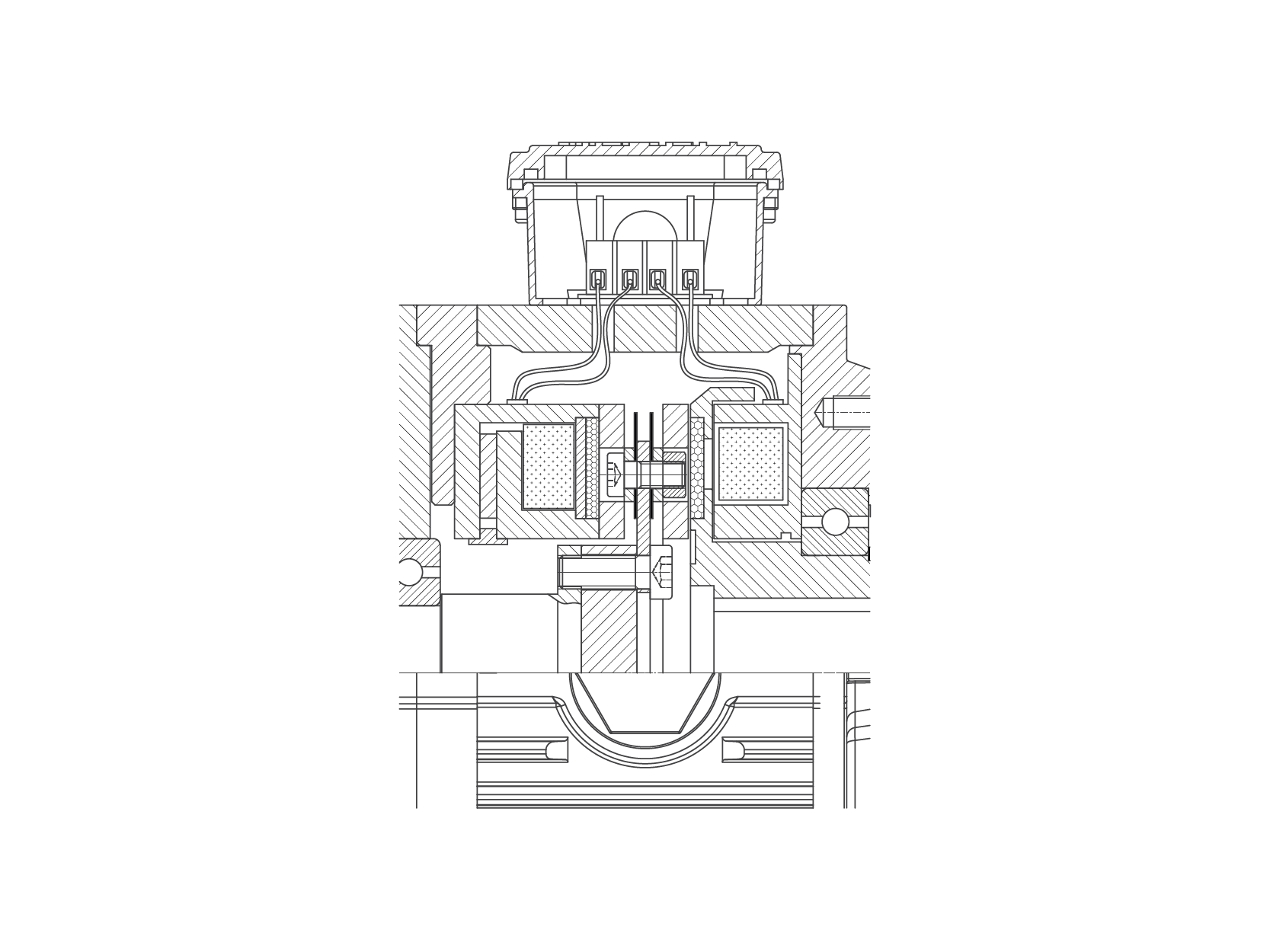

The DFK series clutch-brake combination is uses in situations where there is synchronous operation. The

combination consists of DRK current applied clutch and DAF series current applied brake. When the DRK

series clutch is de-energized, the shafts rotate independently of each other. When energy applies to the

brake coil, the coil becomes an electromagnet, which creates a magnetic flux. This magnetic flux ensures

the pressure flange to pull towards the brake coil, allows shaft and armature to rotate at the same speed.

Thus come true torque transmission. When energy is applied to the coil of the DAF series brake, the coil

becomes an electromagnet, which creates a magnetic flux. This magnetic flux ensures the pressure flange

to pull towards the brake coil and braking. When de-energized the lamella spring, which is connected to

the pressure flange, separates the pressure flange from the brake coil and ensures finish the braking.