You can find more detailed information and technical data in our catalogue.

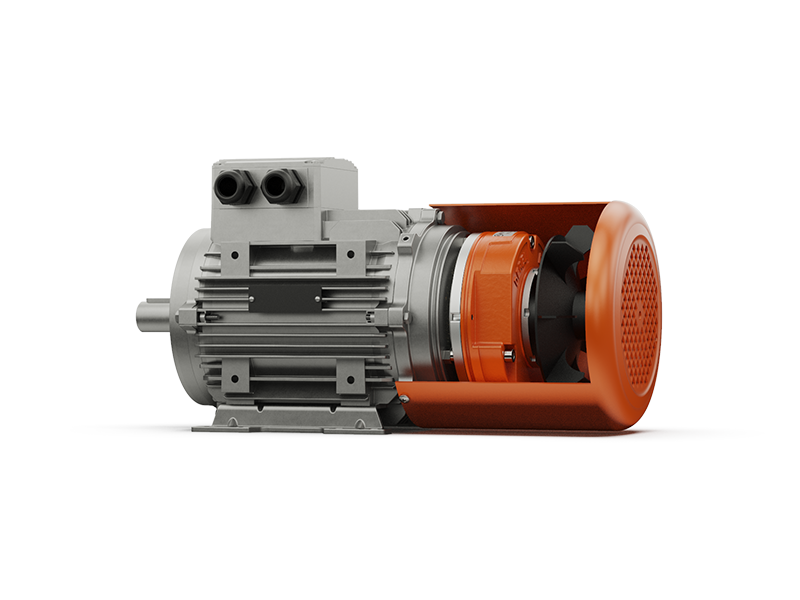

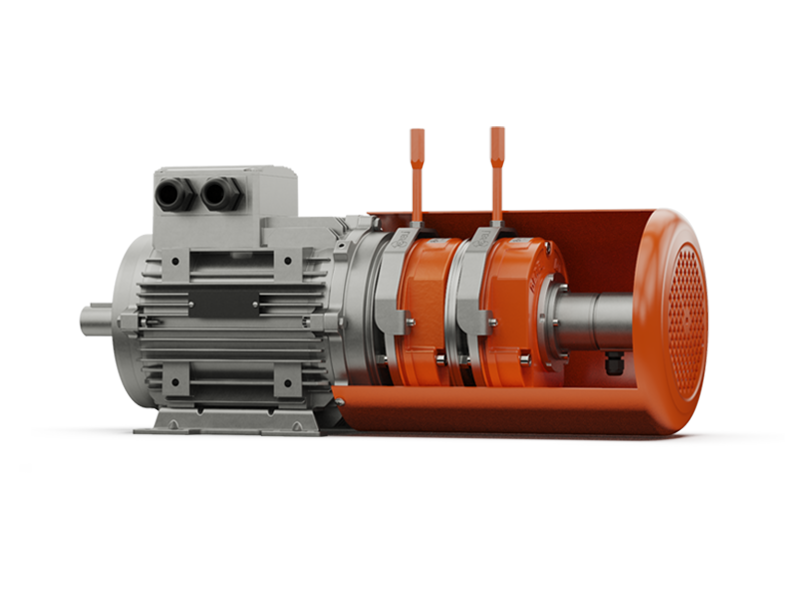

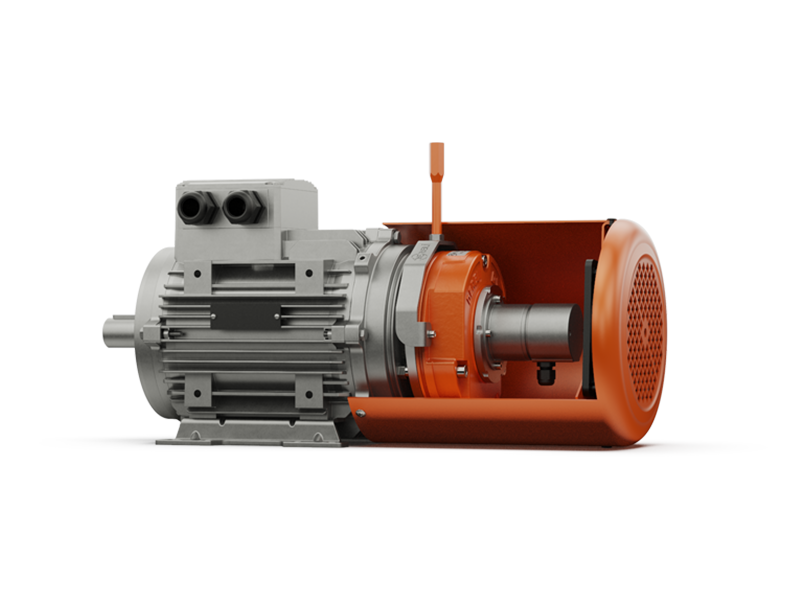

Operating Principles

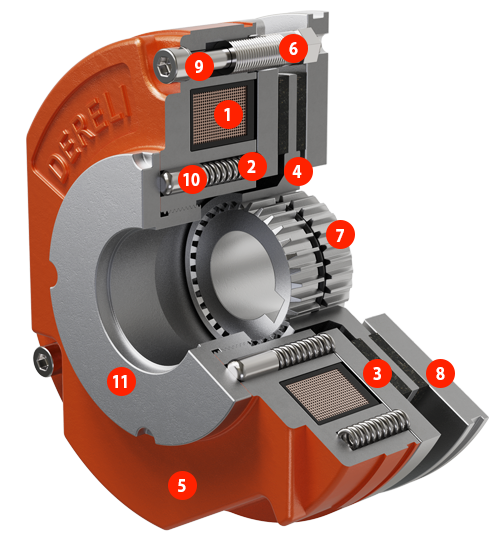

DYF series brakes are spring applied brakes and do the braking when energy is

not applied.

When energy applies to the brake coil (1), a magnetic field creates.

This magnetic field overcomes the force of the pressure springs (2) and ensures

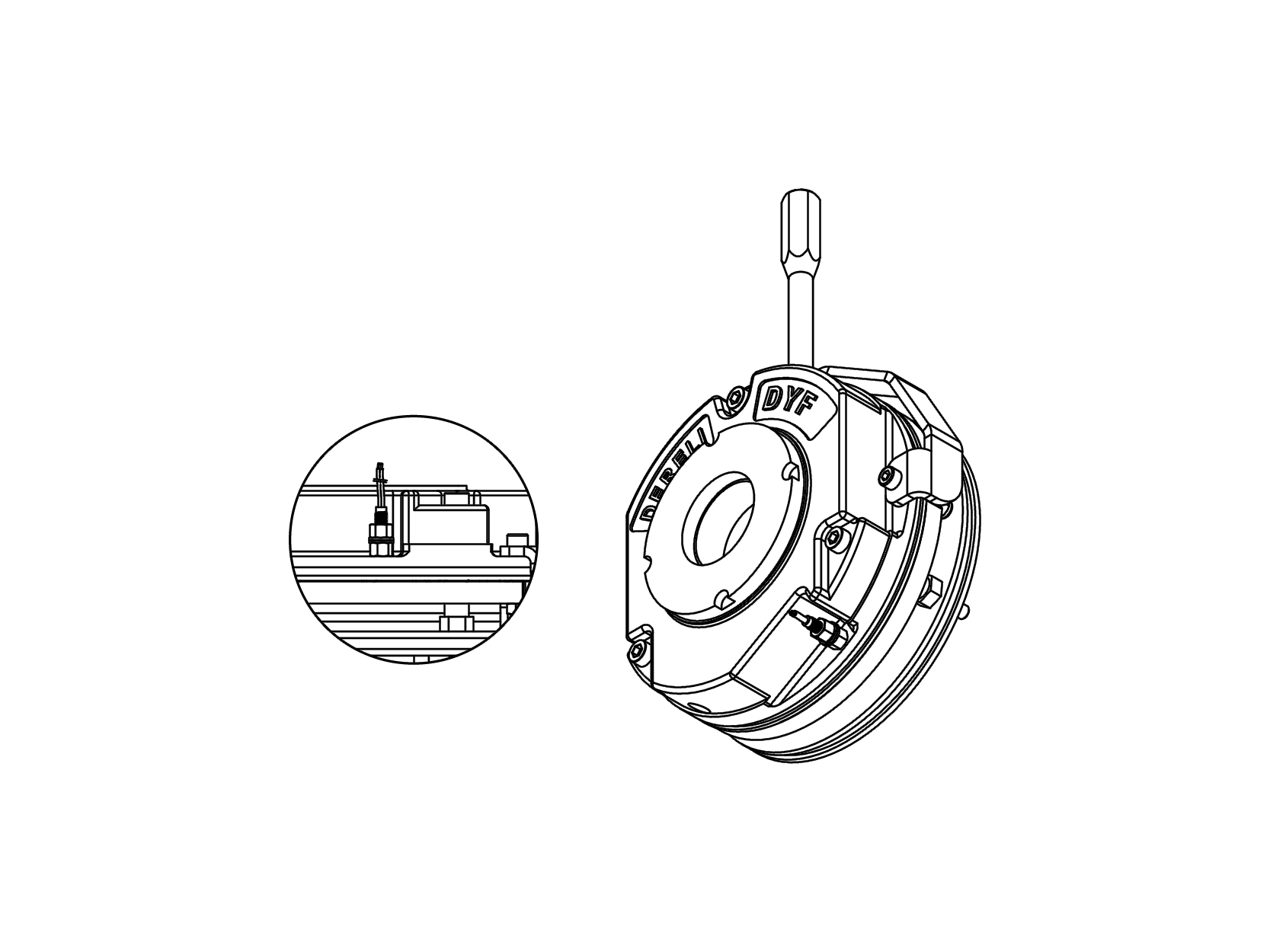

that the pressure flange (3) compresses the springs and pull them towards the

coil.

As a result, the brake pad (4), which has friction surfaces on both sides,

releases. When the energy is cut off, the magnetic field disappears, the

compressed springs releases and they ensures the pressure flange to be push

towards the brake pad and braking.

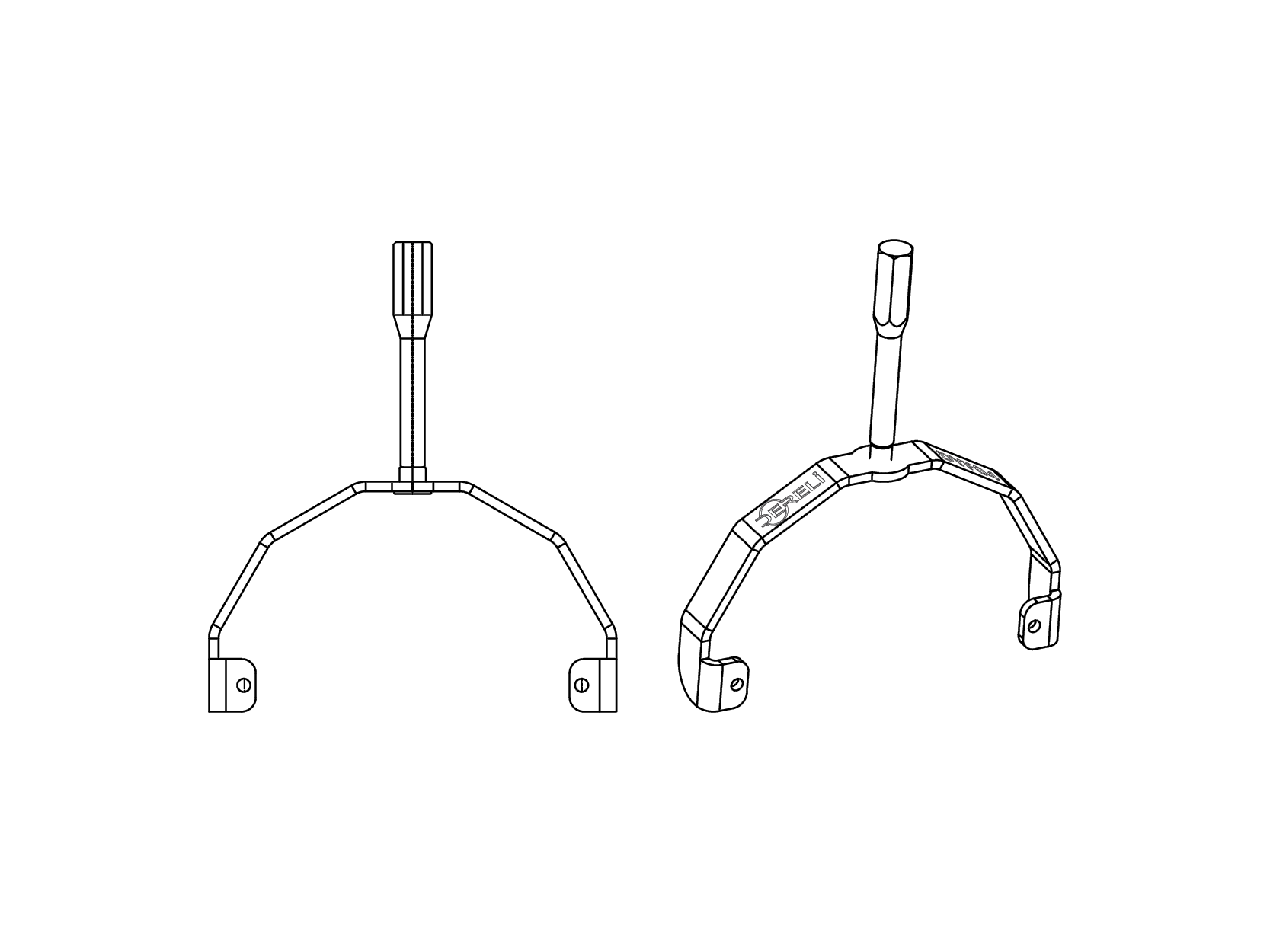

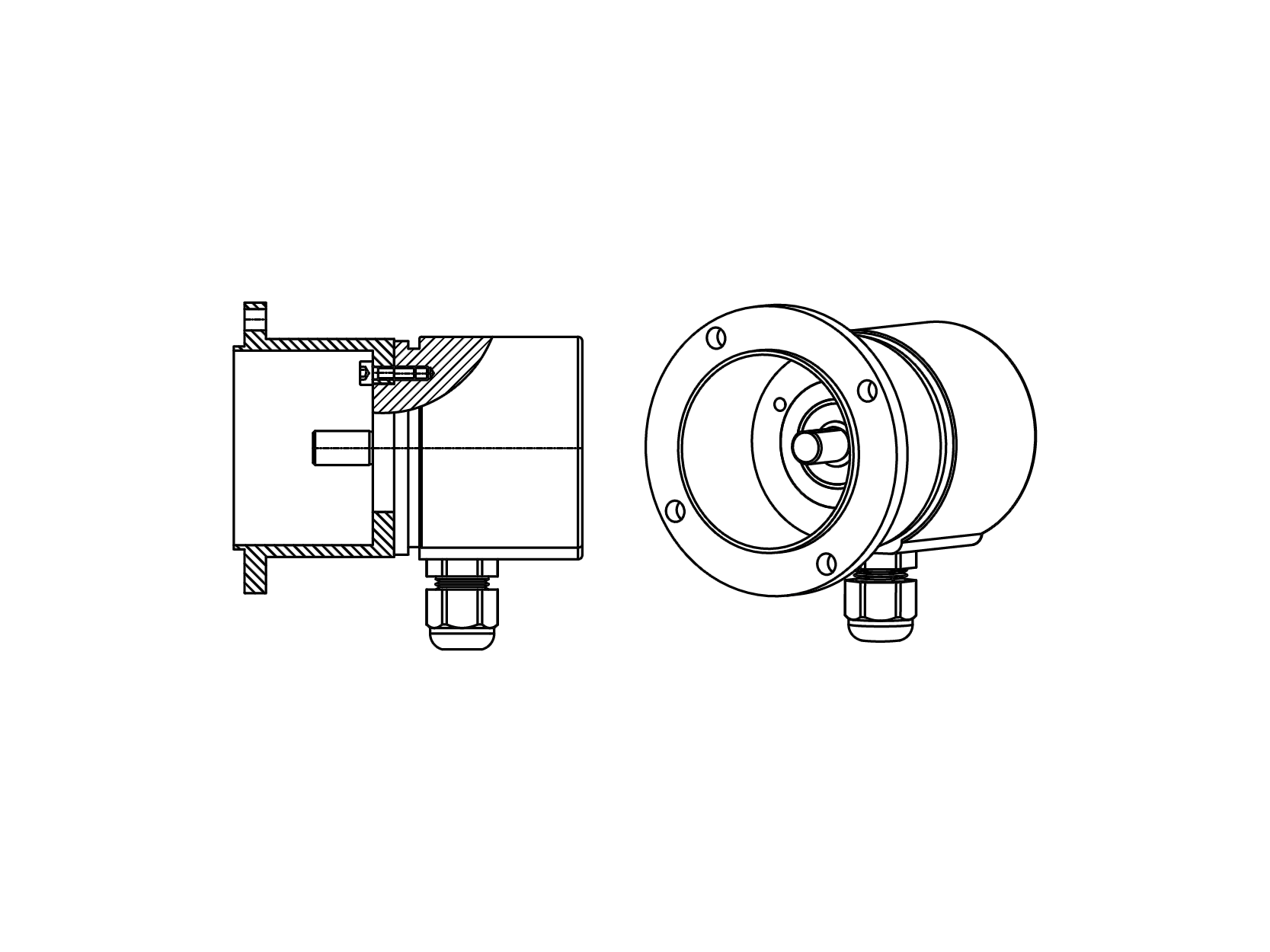

1Brake Coil

2Pressure Spring

3Pressure Flange

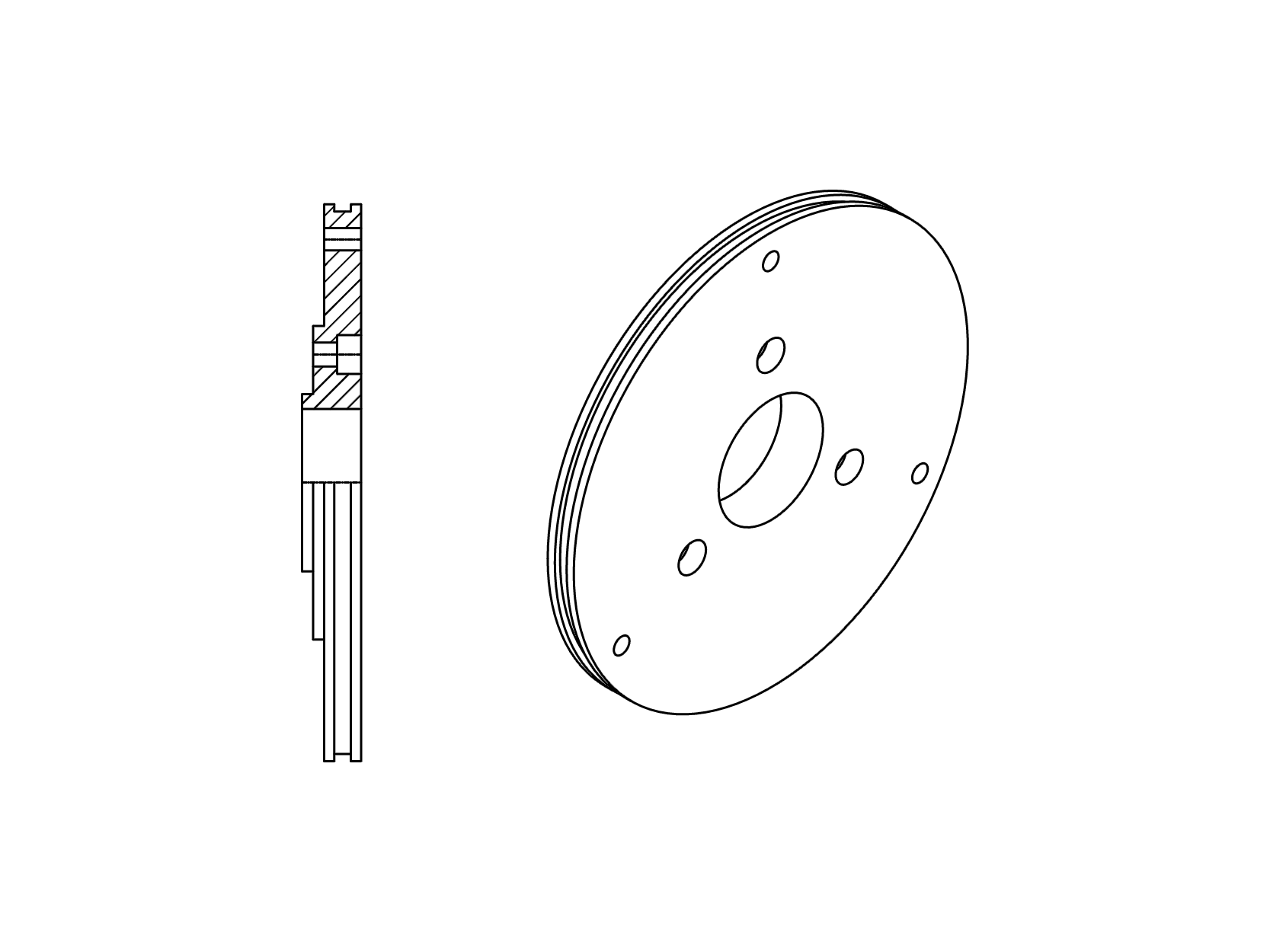

4Brake Pad

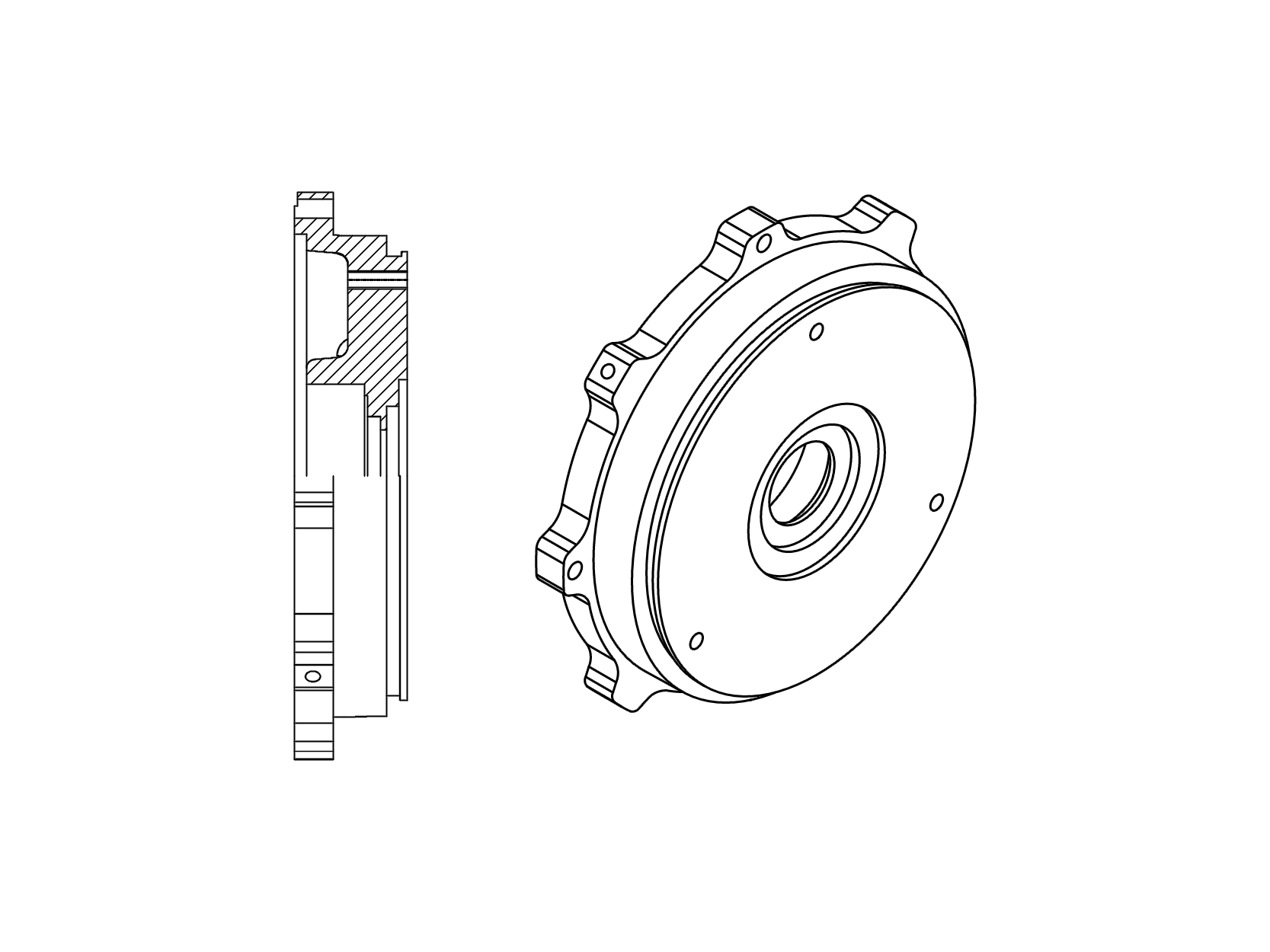

5Brake Body

6Working Gap Adjustment Bolt

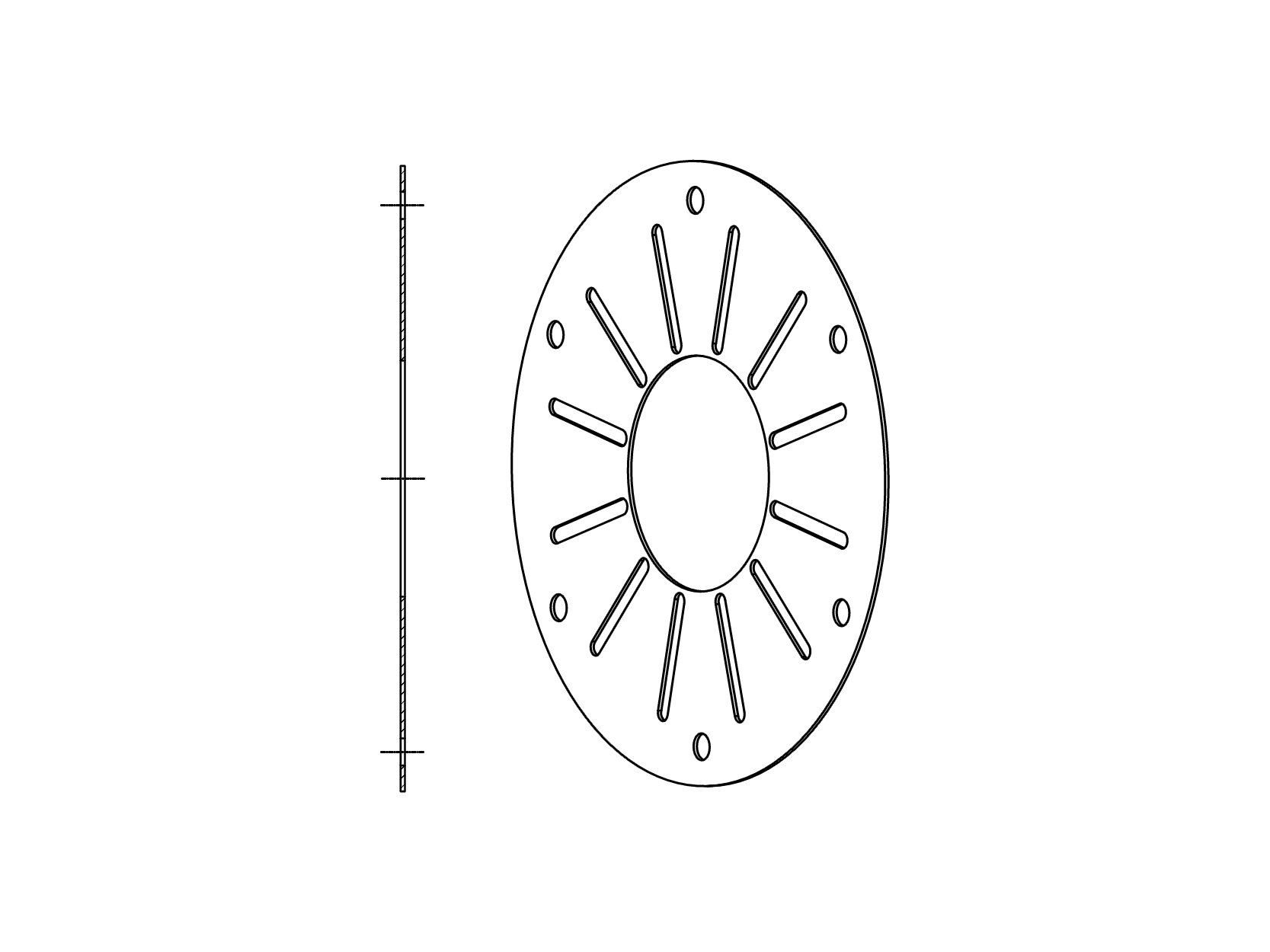

7Brake Hub

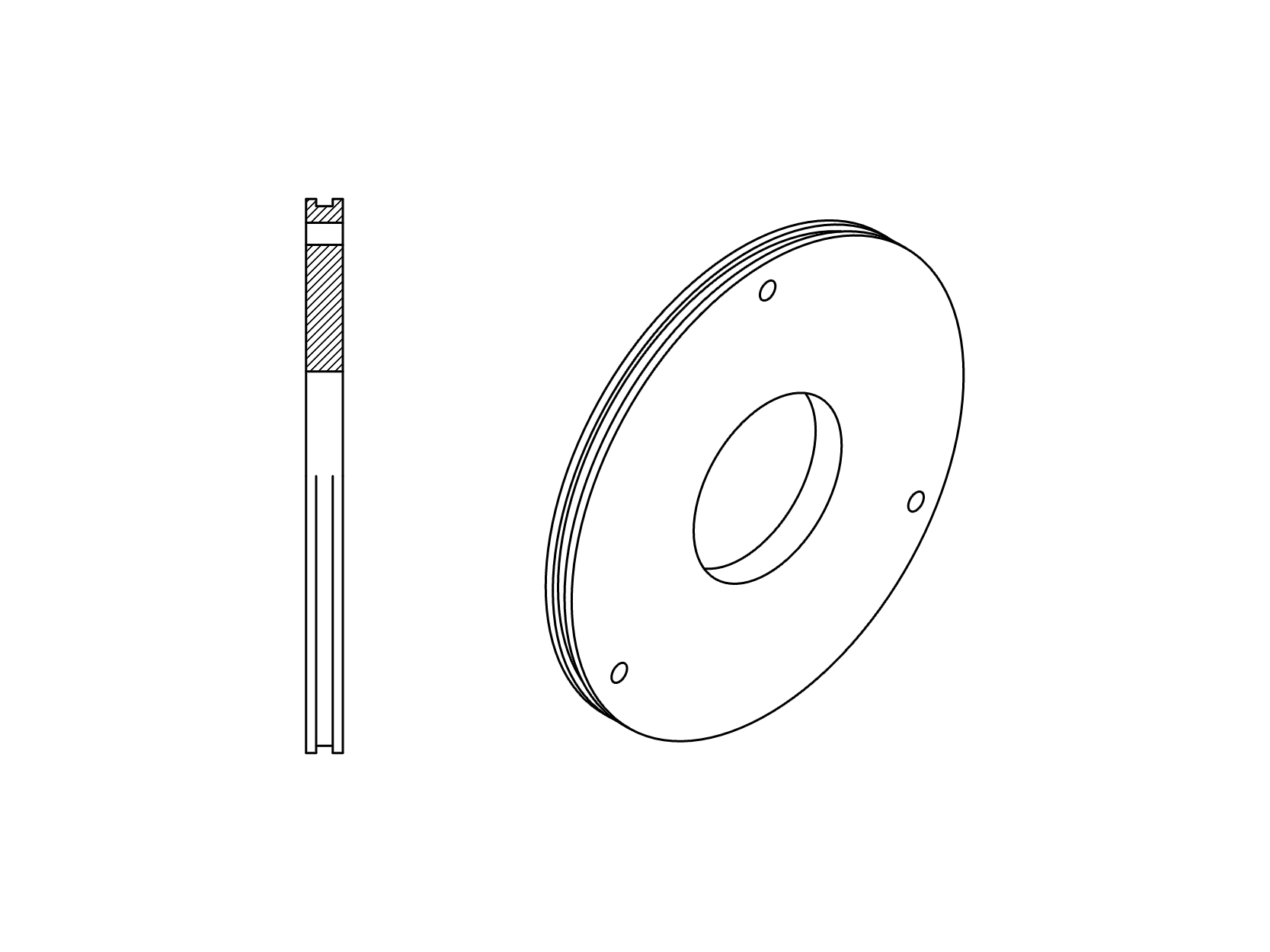

8Mounting Flange

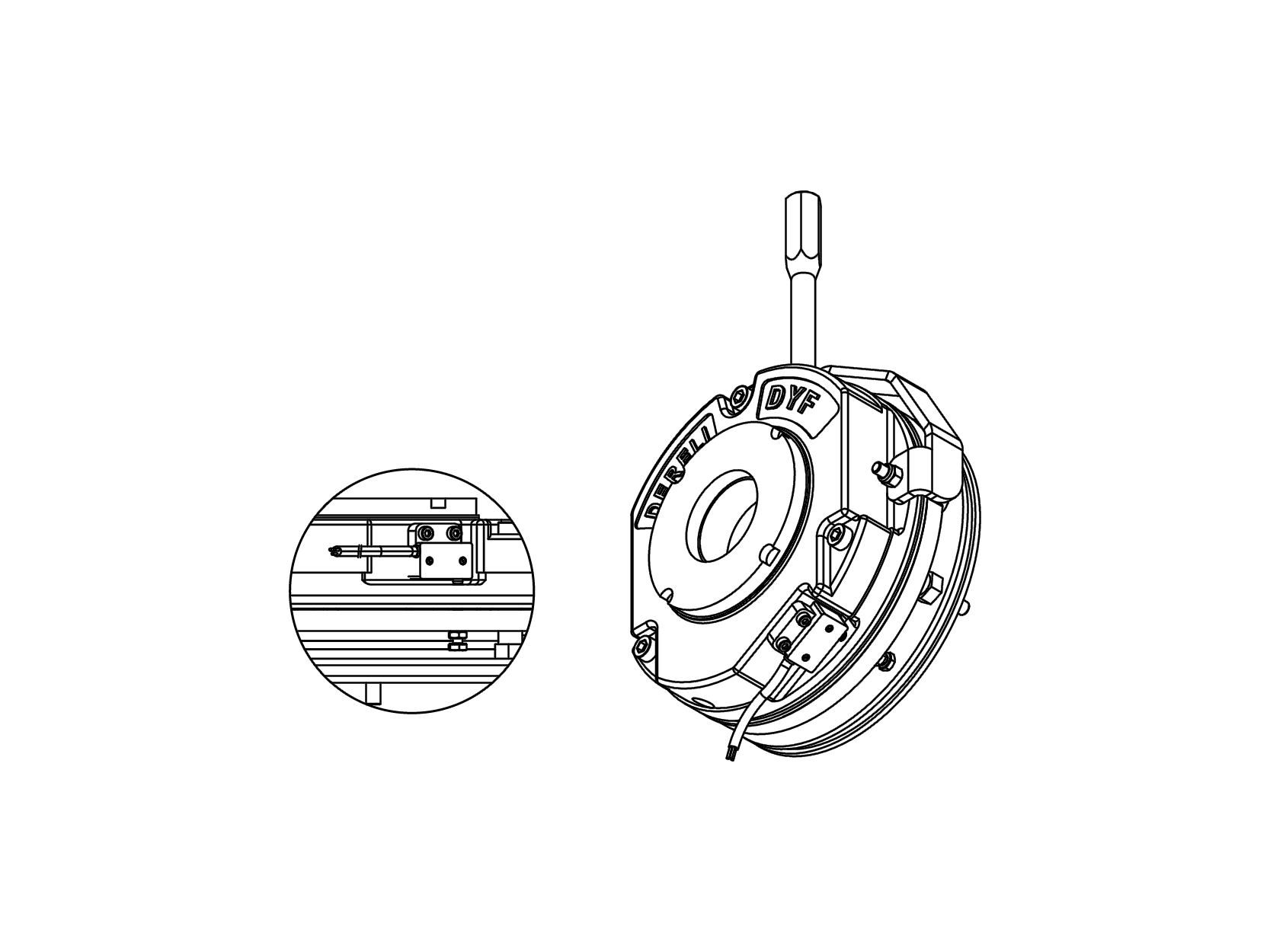

9Brake Connection Screw

10Pressure Pin

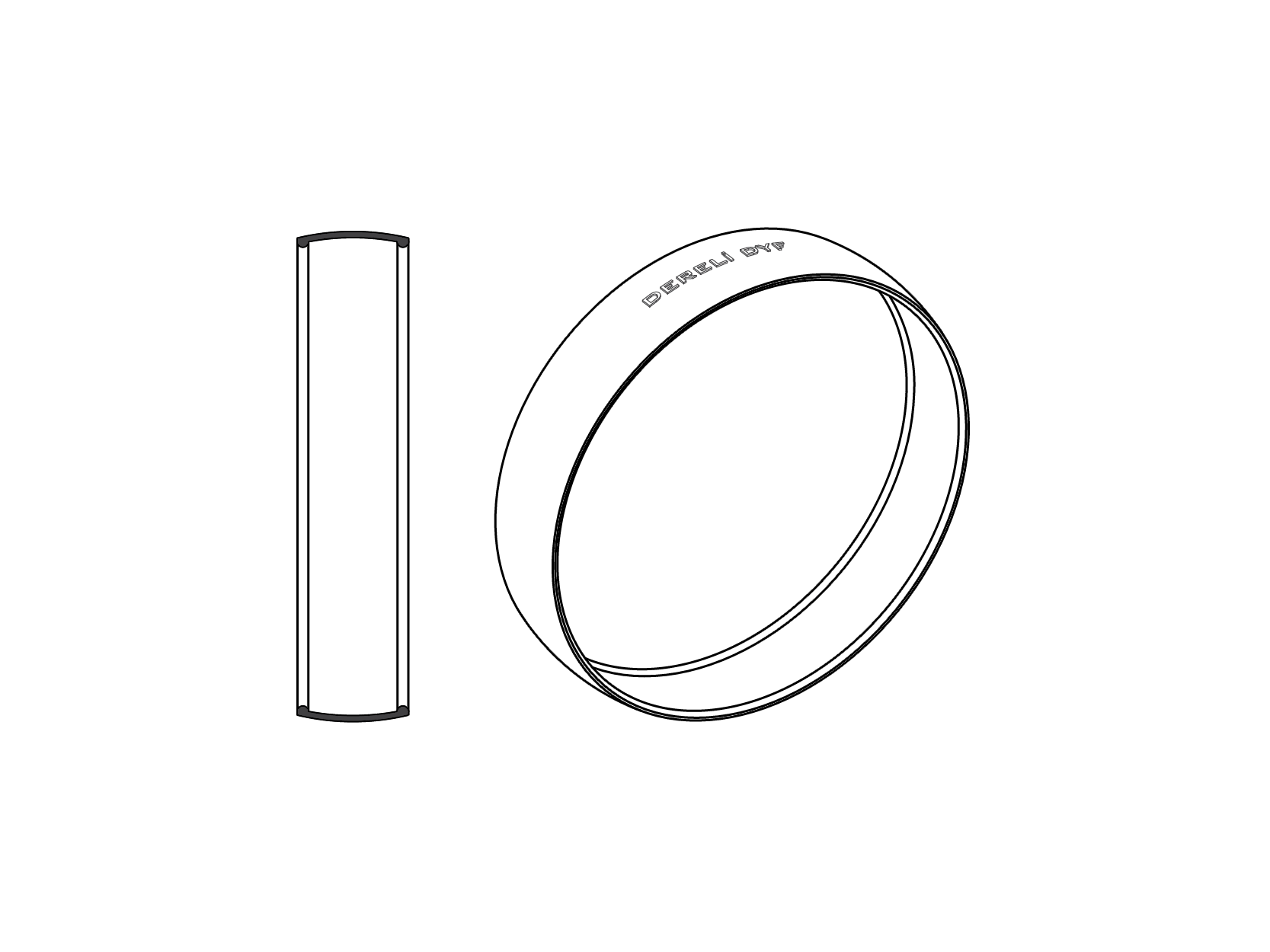

11Torque Adjustment Nut