You can find more detailed information and technical data in our catalogue.

Click to PDF Catalog

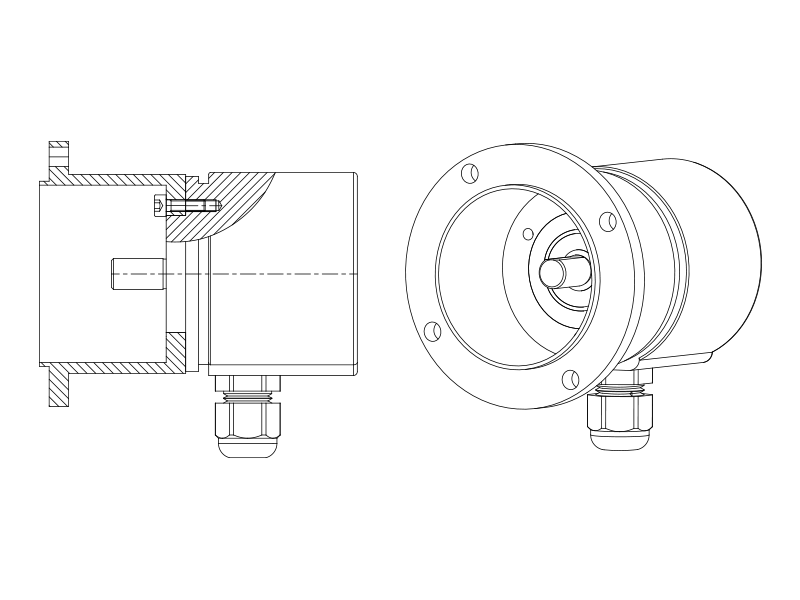

Product Features:

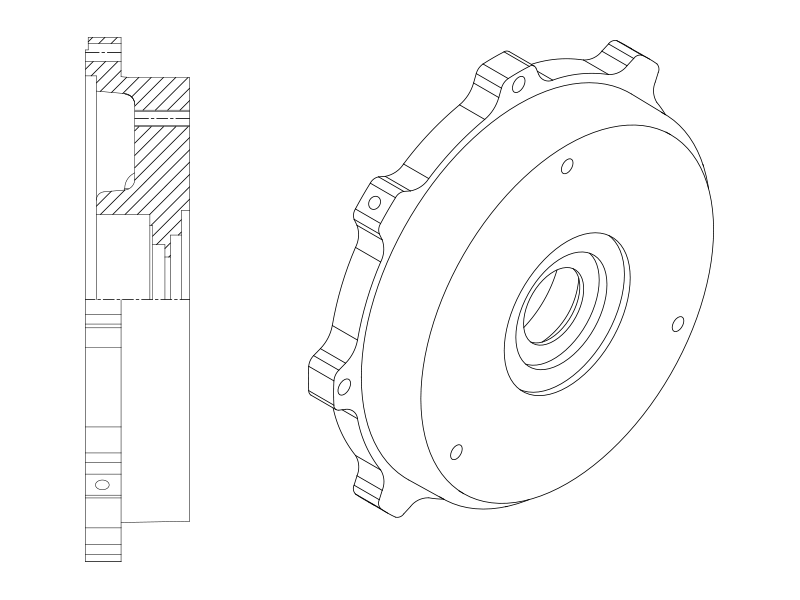

1Brake Coil

2Pressure Spring

3Pressure Flange

4Brake Pad

5Brake Body

6Working Gap Adjustment Bolt

7Brake Hub

8Brake Connection Screw

9Double Brake Connection Hole

10Sealing Ring

11Cable Exit Grand

12Blind Cover

You can find more detailed information and technical data in our catalogue.

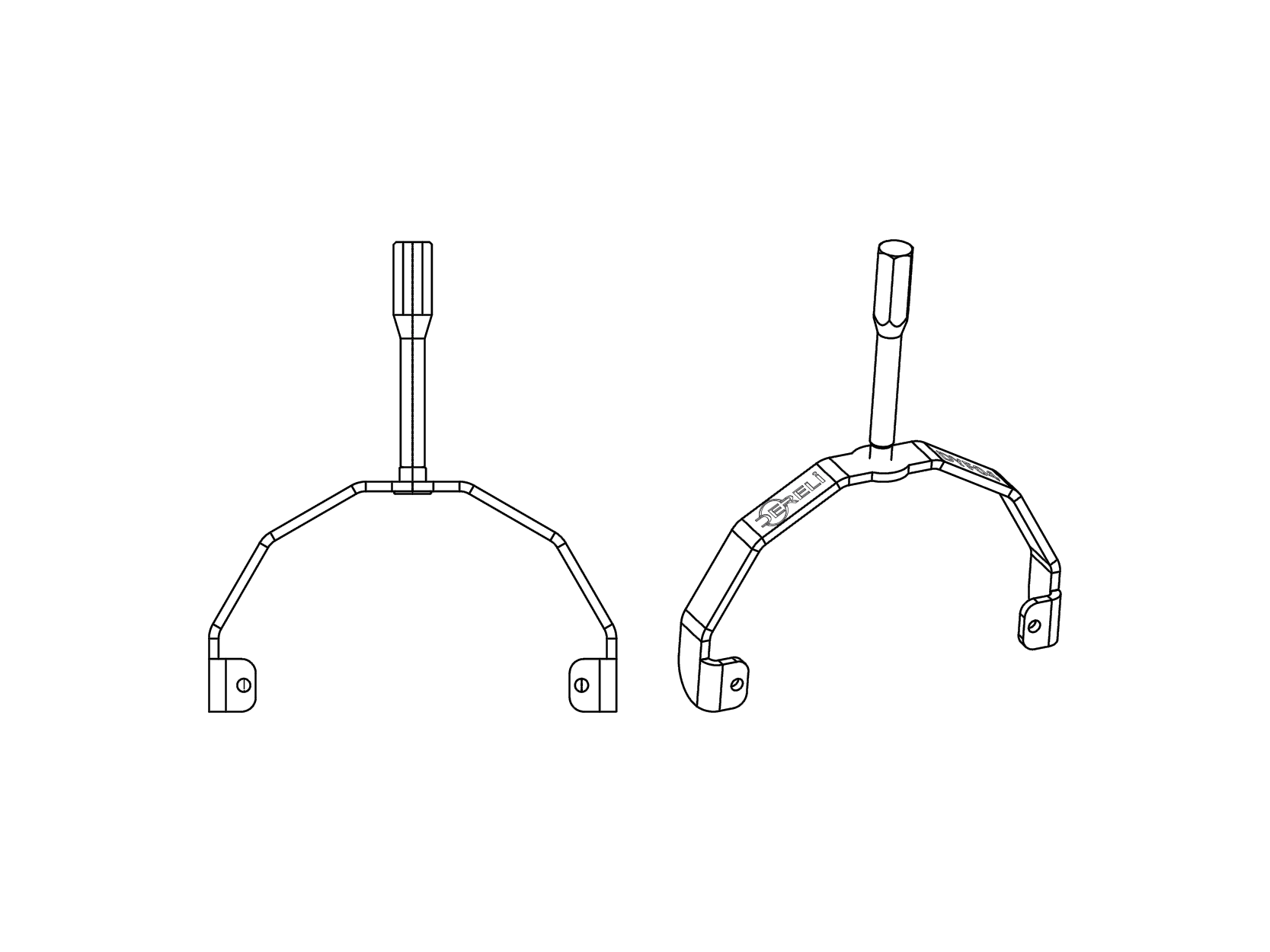

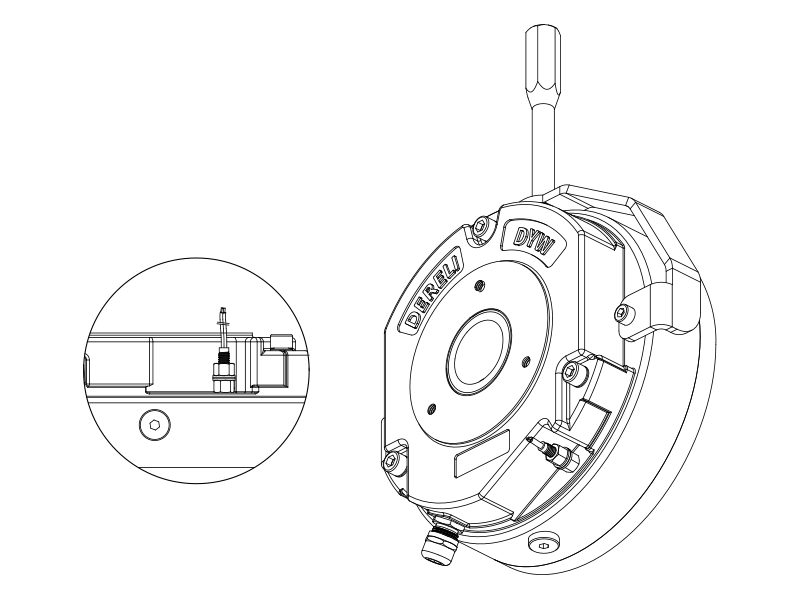

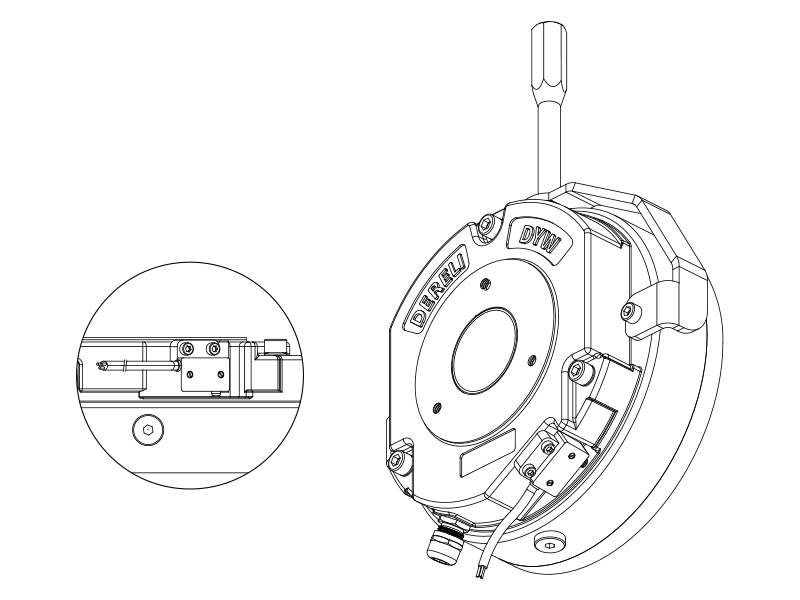

Hand Release (MK)

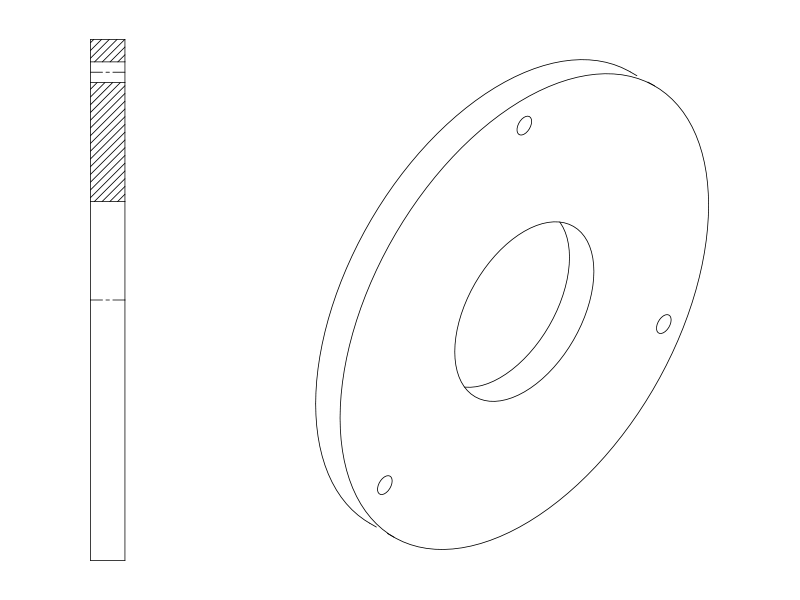

Mounting Flange

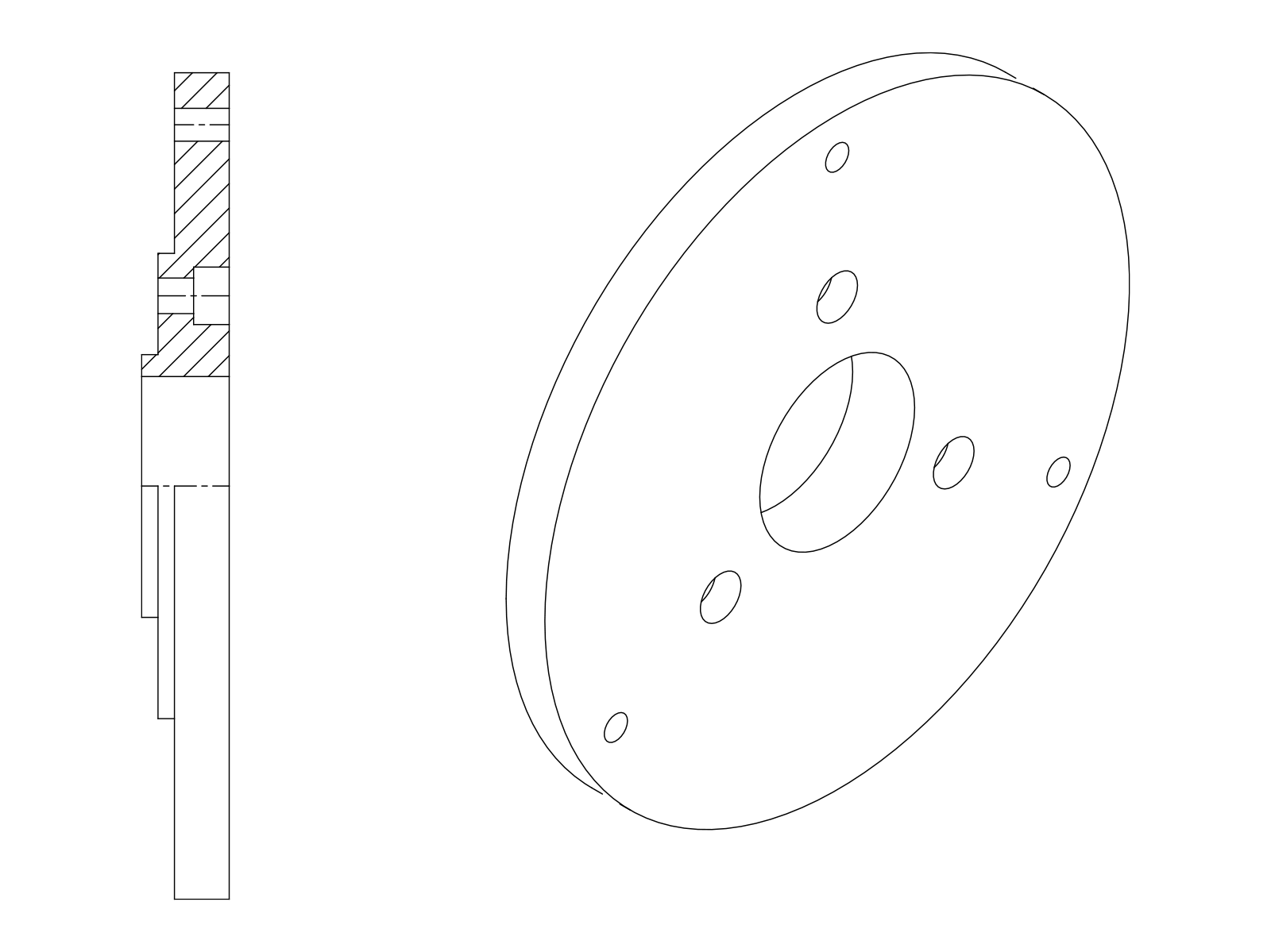

Double Brake Mounting Flange (DB)

Encoder Flange

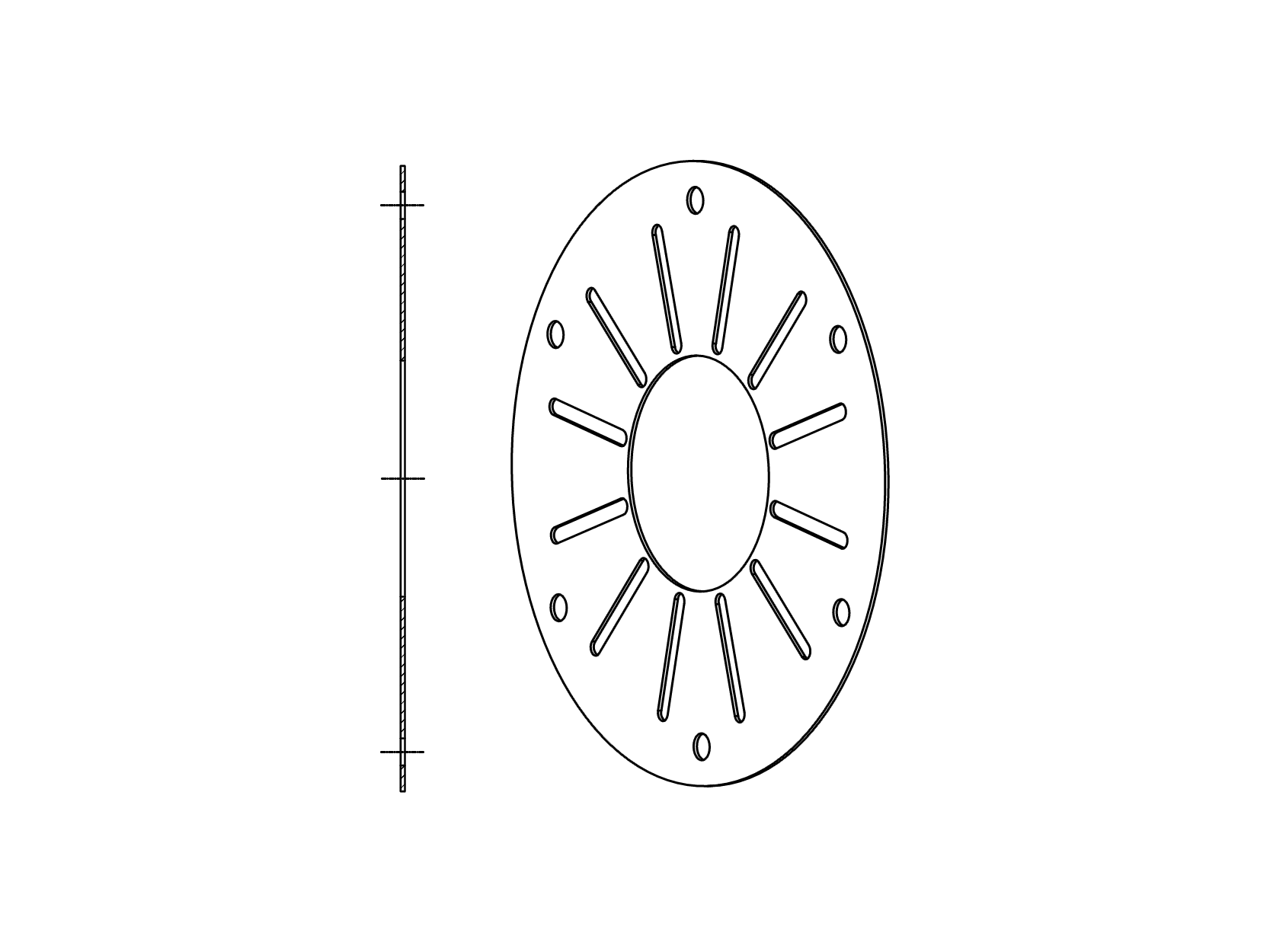

Stainless Steel Friction Plate

Proxymity Switch

Micro Switch

Motor Connection Cover

For more detailed information about the products in Dereli, please click on the titles.